Super Duplex Stainless Steel composition and its Benefits

What is stainless steel?

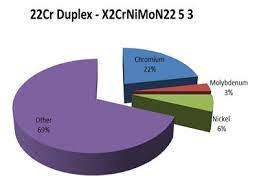

Stainless steel is a term originally coined in the development of culinary products. Now, it is more widely used and covers a large range of stainless steel composition types and grades for corrosion and oxidisation resistant applications. Iron alloys with at least 10.5% chromium make up stainless steel. It can be combined with other elements such as nickel, titanium and copper for added strength and toughness. It does not rust or stain easily as ordinary steel does, therefore it is often used in environments where corrosion is an issue.

What makes it Super Duplex?

Duplex stainless steels are an equal mixture of ferrite and austenite and depending upon the other elements contained within it, can vary how resistant to corrosion it is. Super Duplex stainless steels are so called due to their high content of alloys, making it high performance and highly resistant to corrosive materials. It is also characterised by the higher chromium content, usually between 12 and 19%.

What are Duplex and Super Duplex stainless steels used for?

Due to the low maintenance and corrosion resistant nature of stainless steel, it is used in many different industries such as building, architecture, bridges and aircraft. Stronger stainless steels such as duplex and Super Duplex, are especially useful when used in the chemical industry for example, building tankers and containers. As chemicals need to be stored safely and securely, only the strongest materials can be used. It is not just the containers and vessels which need to be highly resistant to corrosion within the chemical, and indeed many of the industries listed above, the pipes, welding, tubes, fans and rotors to name but a few components, must also be tough enough for the job. Super Duplex materials are being improved all the time and so can also be used as an alternative to expensive nickel alloys in even the most demanding locations such as hot tropical water where only the toughest materials survive in the harsh salt water conditions.

What are the benefits of Super Duplex materials?

Super Duplex stainless steel is popular in industry as it is easily workable and can be welded without too many problems. The high strength of the material makes it a good choice to use where structures need to be strong, safe and unyielding under pressure. In the aircraft industry, all materials come under a great deal of pressure, from extreme heat and extreme cold, chemicals to fuel and lubricate joints, plus the immense air pressure components are subjected to. Due to the nature of the aircraft industry, it is important to use materials which can handle the varying temperatures and which don’t crack, buckle or erode under stress. Safety of those in the aircraft and those on the ground is paramount so only the highest performing materials are used. The mechanical strength of Duplex and Super Duplex stainless steel make for lighter constructions and more compact designs, perfect for industries where size, weight, cost and length of construction time are limiting factors.