Mechanical Water Flow Meter and How it Works

A mechanical water flow meter is a device that gauges the speed of water that flows in a tube. The flow meter comes with a wide range of designs. Each type is excellent on its own when it comes to how it works to its uses in the industry. This article will learn more about the different designs of mechanical water flow meters and how they work.

Vane flow meter

Vane meters are a type of variable area flow meter. It gauges the flow of fluid moving in a vessel. Vane meters have a vane spring, and this vane is driven by the flow against the spring depending on the flow rate. To get the data from this meter, you can link it with a transmitter.

Velocity Flow Meters

The velocity flow meter gauges the fluid’s flow rate by calculating the speed of fluid that moves through it. In this device, the fluid’s speed offers a direct gauge of its flow rate as they are directly related to each other.

There are many ways, such as using a turbine you use to gauge the speed using this meter. Like other meters, velocity flow meters come with diverse designs depending on how they measure the speed. Some of these types include:

- Propeller flow meter

- Single jet flow meter

- Pelton wheel flow meter

- Sonar flowmeters

- Ultrasonic meter

- Pitot tube flow meter

- Multiple jet meter

- Vortex shedding meter

Those fluids that are found in dangerous places demand the use of non-intrusive meters to gauge the flow rate. A sonar flow meter is a primary device used with such fluids.

Float flow meter

Afloat flow meter is a type of variable area flow meter. It has a float inside made by the viscosity, flow rate, and density of the product you intend to use. The device also has a tube with a flow scale on it.

For you to install this meter, you have to mount it vertically with the flow going upwards. Whenever a fluid moves through this meter, it creates a velocity on the float showing the related flow rate on the scale.

Differential Pressure Meter

When it comes to DP meters, the flow is gauged by calculating the drop in the force as the fluid moves through the obstructions put into the path along which it flows. That is because the flow of the liquid in the pipe rises, and there is more drop-in force across the constriction for recording by a meter.

With that, you can now get the flow rate as it is proportional to the square root of the force drop. Below are some of the main types of this meter.

- Cone meter

- Venturi tube meter

- Variable area flowmeter

- Target flow meter

- Laminar flow meter

- Orifice plate flow meter

- Elbow tap flow meter

- Flow nozzle meters

- Dall tube flowmeters

- Pilot tube meters

- Flow tube flowmeters

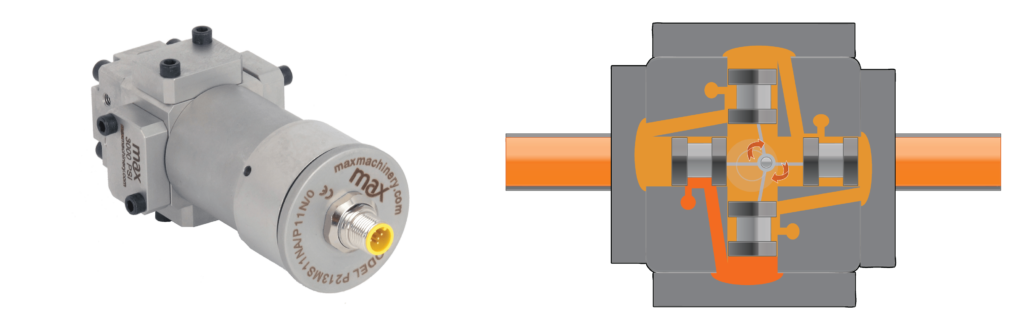

Piston Flow Meters

Piston meters work under the law of a piston oscillation within a casing of determined volume. These devices are mostly used in domestic water usage gauging. In every flux, a fixed amount of fluid moves across the piston casing.

The flow meter dial is applied to add piston oscillation through a gear linked to this piston. That helps in knowing the amount of fluid passed through the pipe in a certain amount of time.

If you wish to calculate the volumetric flow rate, divide this volume recorded above by the fluid’s total time.

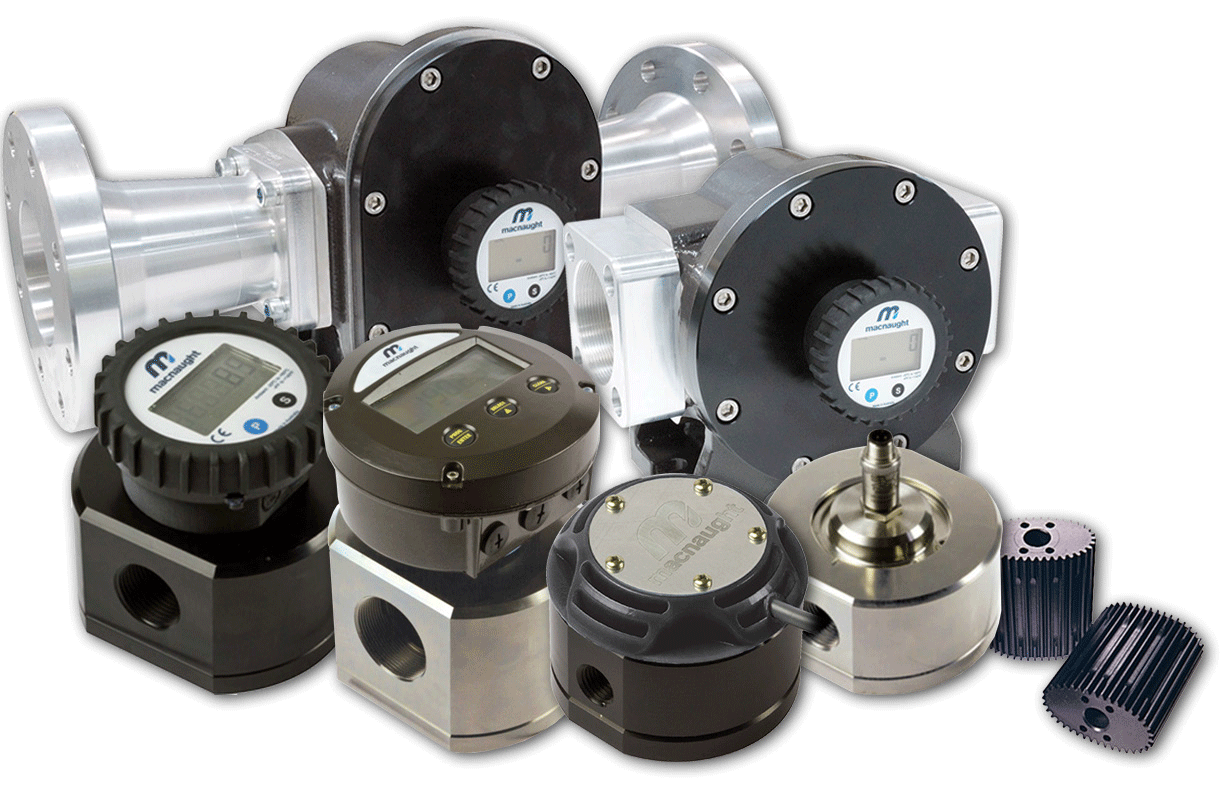

Positive displacement flow meter

DP meters gauge the flow rate by measuring the volume of the fluid flowing through them. This process entails an entrapment of the liquid into a particular container to know its flow rate. In real life events, it’s the same way that we allow water to fill a jerry can up to a certain level.

DP meters can gauge the intermittent flows or even merger flow rates. They are ideal for any liquid, no matter their density or viscosity. This meter is very robust since the turbulence cannot alter it in the pipe. Some of the most used designs of this meter include:

- Rotary piston meters

- Nutating disc meters

- Oval gear meter

- Helical gear meters

- Oscillation flowmeters

- Gear flowmeters

It has so many uses, and that makes it a reliable solution in many sectors. The DP flow meter has two spinning parts and an excellent accuracy chamber. Typically, the flow fills the gap between the rotors, moving them as the fluid faces downstream to the meter.

Mass Meters

In this device, the volumetric flow is directly related to the spinning of the rotor. You get to know the flow rate estimate using this device by gauging the fluid’s mass flowing through the meter. The meter is ideal for chemical firms that focus on measuring the weight more than the liquid volume.

The most used types of this meter are the thermal meters and the Coriolis flow meter. In thermal meters, the fluid flow cools the probe, which is then pre-heated to a certain level. The heat loss is used to gauge the rate at which the fluid moves.

Coriolis flowmeters operate under Coriolis’s law, where the fluid moves across a vibrating pipe, causing a change in the frequency or shift that offers a gauge of its flow rate.

Variable Area Meters

These meters consist of a vertical tapered glass tube and afloat in the pipe. The sharp lines are aligned so that the increase in the flow pushes the float up. That is due to the raised force and viscous forces, and the float is pulled down by the gravity in case the flow rate lowers.

Final Words

A water flowmeter is a tool that can gauge the amount of water flowing in the pipe. As you have noted above, a mechanical meter is one of the primary water flow types. The mentioned above types are just the most used designs, but the mechanical meter has more types. Ensure you choose carefully an automatic meter that meets your needs in your next purchase.