Discussion on Various Types of Flow Sensors

A flow sensor is a device used to gauge the flow rate of a fluid. On the other hand, a Flow controller is an electric tool that monitors and keeps the flow rate variables in a process. If you wish to know more about the diverse designs of flow sensors, sit back and relax. Below is a discussion on flow sensor types.

Magnetic Flow Sensor

The magnetic sensors work under the law that states that a conductor’s motion in a magnetic field induces a voltage. These devices comprise a flow pipe that produces a magnetic field in the tube. They also have an electronic converter that gauges induced voltage.

Magnetic flow sensors have no force drop and no parts that are bound to wear out. That is because there is nil obstruction such as viscosity, solids, and contaminants in the tube. These flow sensors are viral and have very accurate results. But, to keep the precise output, you need to ensure that your sensor has a flow rate of more than 1.5 fps. One of the main drawbacks to this sensor is that it requires a conductive fluid to operate.

Laser-Doppler Sensors

These devices are a bit different from other sensors since they gauge the flow rate at a point and not the whole area like other devices. Usually, they are used to scan a flow field to get specific data. These sensors work under a law that entails the crossing of two laser beams in the flow field. In return, it creates a barrier fringe pattern with alternating light and dark regions.

If the flow moves through these patterns, the light reflected by particles in the fluid follows the light density and variations, brighter and darker. Did you know that the frequency of the cyclic variation is directly related to the speed flow?

Laser-Doppler gauges the speed in mm per second range at the low end and a little thousand m/sec at the high end. These devices are ideal for following the significant speed transients since they give very accurate readings.

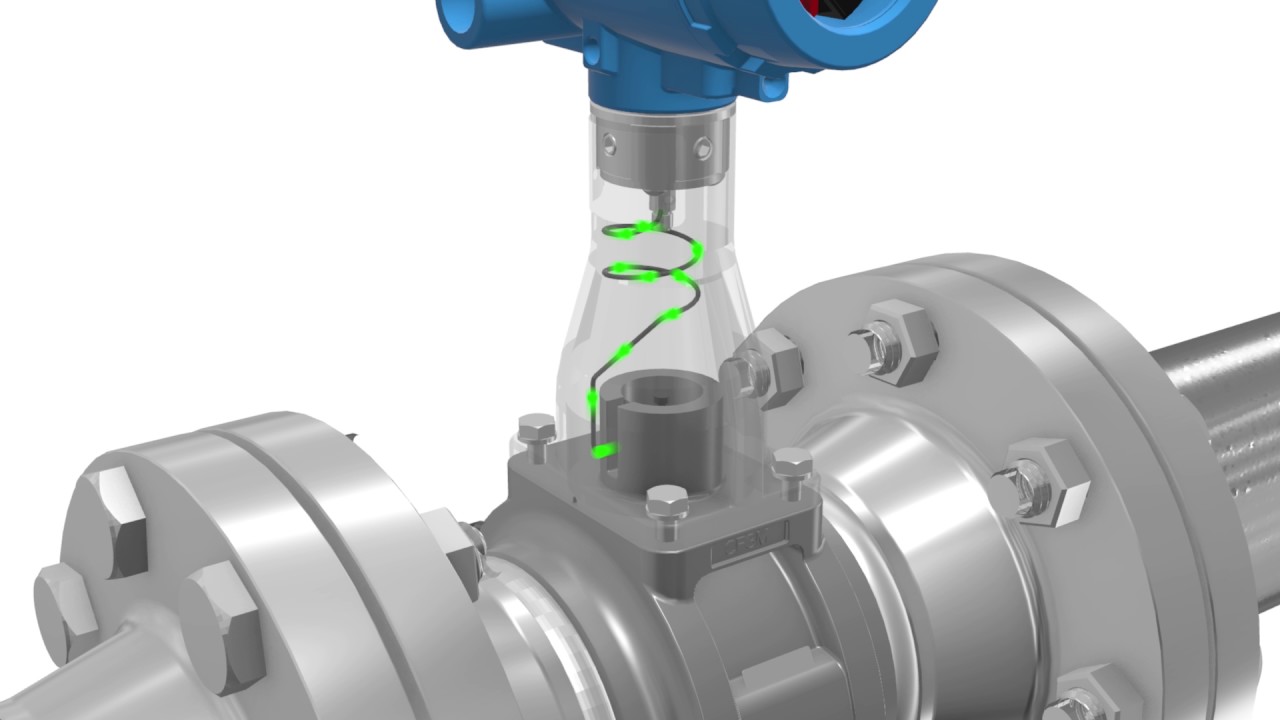

Vortex Flow Sensors

The vortex flow meters define the flow from a blunt object’s viscosity effects in a flowing stream. When the liquid moves through the object, vortices are created from one side of the item to the other regularly.

By sensing the rate of vortex passage, you can get a gauge of the flow speed. Several sensor dealers have tried to invent new methods to detect the vortex passage. Some have failed, while others have succeeded. Piezoelectric crystal element is one of the compelling methods introduced in the market. This device senses the induced strain in the shedder bar. A diaphragm force sensor is also a new method used to detect the vortex passage. It is found beyond the shedder bar. The two sensors give an accurate result and have an excellent dynamic range.

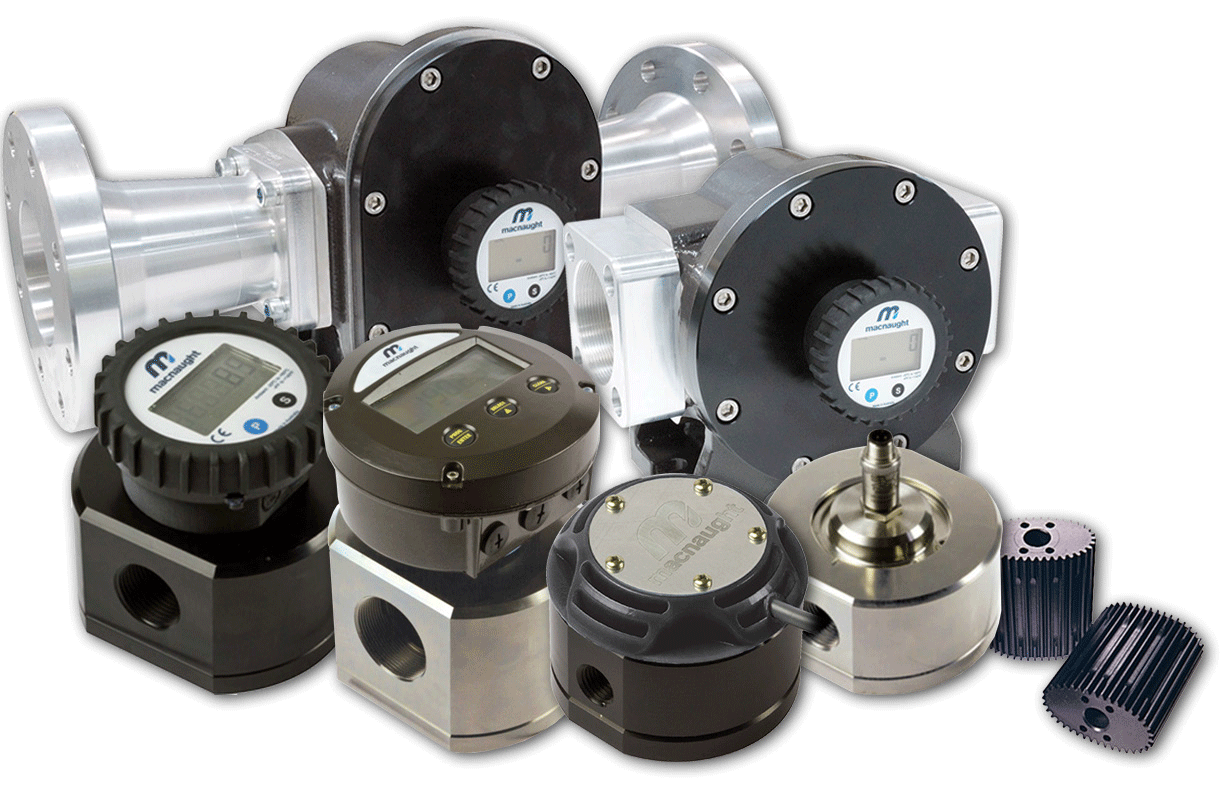

Positive-displacement Meter

The PD meters give the ultimate in volumetric accuracy. Yet, they need most barriers with the flow stream.

In a nutshell, these devices operate like the hydraulic or pneumatic motor. They have an output shaft of the motor-like tool driving the readout. These meters are ideal for very high forces since they are similar to pneumatic and hydraulic motors. One of the main merits of using this meter is that it can discern shallow flow, down to little cc per minute. It also gives accurate results with a dynamic range and can move in two directions. DP sensors can be placed in any place of your choice, making it ideal for all fluids.

Orifice-plate Flow Sensor

Orifice sensor is the most used device in the industry. It is a circular plate inserted in a tube with a round hole drilled in the plate center. The hole must match the system flow range and traits. The force taps on every side of the orifice plate gauge the force gulf, and a wire creates a sign that is the same as the square of flow rate.

Since the link between the flow and the force entails a square root, the gulf drops off quickly as the flow lowers. That makes this sensor have a limited dynamic range and a varying accuracy depending on the flow rate.

Rotameter Sensors

These unique types of variable meters are widely used in the industry. They come with a tapered tube in which a float is held by the fluid moving up in the box. When the rate of flow rises, the float is lifted higher in the tapered pipe. That is due to the greater orifice area needed around the float to spread the moving fluid. These sensors are ideal for low force flow readings.

Final Thoughts

When searching for the right flow sensor, look for factors such as viscosity of the fluid, type of fluid being gauged, cleanliness, and conductivity. You can also check the accuracy and installation of the sensor itself, to mention but a few. The flow controller is ideal for counting items or monitoring air velocity.